Jul 24th 2025

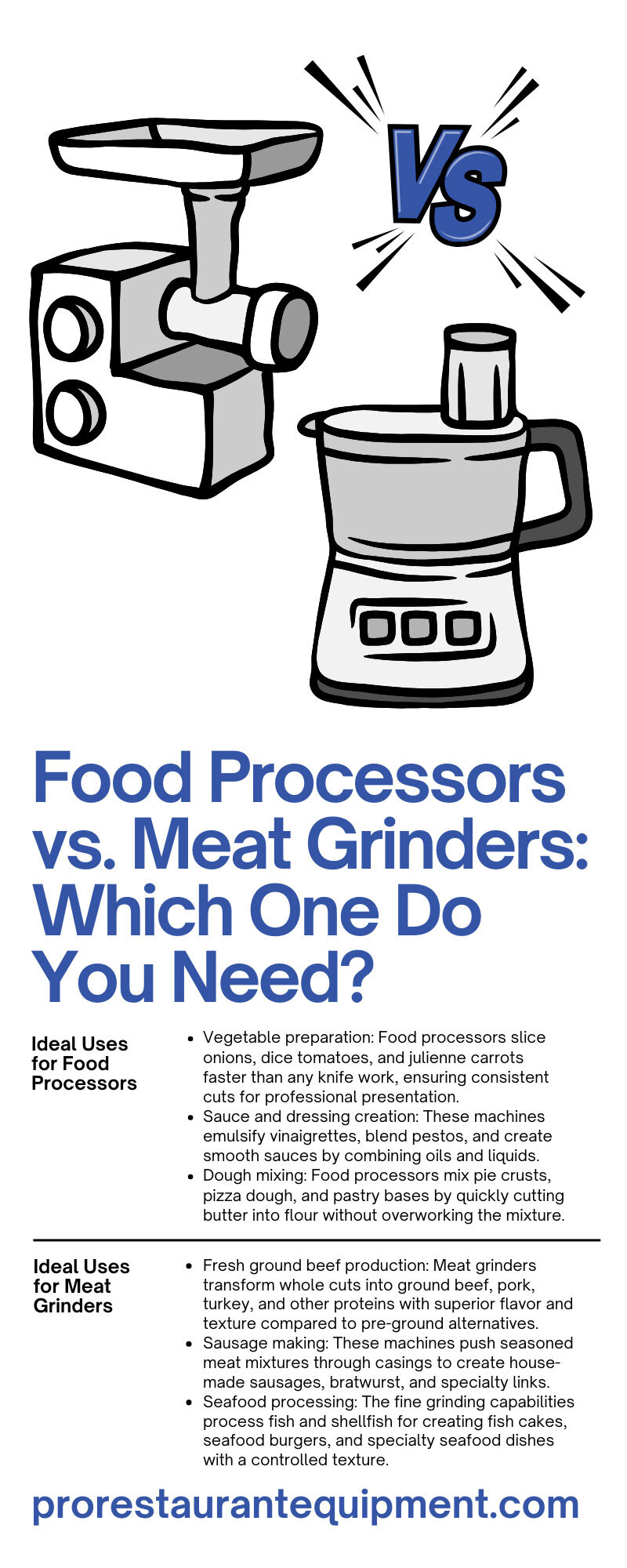

Food Processors vs. Meat Grinders: Which One Do You Need?

Restaurants face countless equipment decisions, but few choices impact daily operations as significantly as selecting the right food preparation tools. Food processors and meat grinders represent two essential pieces of equipment that can transform your kitchen’s efficiency and output quality. Both serve important functions in commercial kitchens, but they excel in different areas. Understanding their unique capabilities will help you make the right investment for your establishment’s specific needs.

What To Know About Food Processors

Food processors are versatile electric appliances that use rotating blades and discs to chop, slice, shred, and puree various ingredients. These machines feature a large work bowl with a locking lid and multiple interchangeable attachments. Restaurant-grade food processors typically offer variable speed controls and pulse functions for precise texture control. They handle both wet and dry ingredients effectively, making them valuable for numerous kitchen preparations.

Ideal Uses for Food Processors

Food processors excel at handling multiple food preparation tasks that require speed and consistency. There are several ways commercial kitchens might rely on these machines due to their ability to uniformly and quickly process large quantities of raw ingredients.

- Vegetable preparation: Food processors slice onions, dice tomatoes, and julienne carrots faster than any knife work, ensuring consistent cuts for professional presentation.

- Sauce and dressing creation: These machines emulsify vinaigrettes, blend pestos, and create smooth sauces by combining oils and liquids.

- Dough mixing: Food processors mix pie crusts, pizza dough, and pastry bases by quickly cutting butter into flour without overworking the mixture.

- Salsa and relish preparation: Food processors chop multiple ingredients simultaneously, creating consistent textures for fresh salsas and chutneys.

Pros and Cons of Food Processors

Food processors offer significant advantages for busy restaurant kitchens. They reduce prep time dramatically, allowing staff to focus on other cooking tasks. Plus, their versatility means one machine can replace multiple manual tools, saving both space and labor costs.

However, food processors often struggle with very small quantities, making them less efficient for single-serving preparations. The parts require thorough cleaning between uses, which can slow down the kitchen workflow. Additionally, they cannot effectively handle extremely hard ingredients such as bones or frozen meats, requiring pre-processing for some applications.

What To Know About Meat Grinders

Meat grinders are specialized machines that break down meat into smaller, uniform pieces through a grinding mechanism. These appliances use an auger system that feeds meat through a series of cutting plates and blades.

The meat enters through a feeding tray, then the auger pushes it through cutting blades, and the meat emerges through plates with holes of varying sizes. Most commercial meat grinders come with multiple grinding plates to achieve different textures, from coarse grinds for rustic sausages to fine grinds for smooth pâtés.

Ideal Uses for Meat Grinders

Meat grinders serve specialized functions that focus primarily on protein preparation and processing. They provide restaurants with control over meat quality and freshness while allowing for custom ground meat blends and specialty products.

- Fresh ground beef production: Meat grinders transform whole cuts into ground beef, pork, turkey, and other proteins with superior flavor and texture compared to pre-ground alternatives.

- Sausage making: These machines push seasoned meat mixtures through casings to create house-made sausages, bratwurst, and specialty links.

- Seafood processing: The fine grinding capabilities process fish and shellfish for creating fish cakes, seafood burgers, and specialty seafood dishes with a controlled texture.

- Specialty preparations: Meat grinders handle tasks like creating meat-based spreads, pâtés, and protein-enriched mixtures for various menu items.

Pros and Cons of Meat Grinders

Meat grinders provide exceptional control over meat quality and freshness, allowing restaurants to source whole cuts and grind them as needed. This approach often reduces food costs while improving flavor and texture. They also enable restaurants to offer unique meat blends and house-made sausages that differentiate their menu.

The main drawbacks of meat grinders center on their specialized nature and maintenance requirements. They perform only meat-related tasks, limiting their versatility compared to other kitchen equipment. These machines also require thorough cleaning, sanitization, and maintenance of cutting blades and plates to maintain optimal performance and food safety standards.

How To Choose Between Food Processors and Meat Grinders

Selecting the right equipment depends on your restaurant’s specific operational needs and menu requirements. Consider these key factors to make an informed decision that supports your kitchen’s efficiency and food quality goals.

Reflect on Your Menu’s Preparation Methods

Analyze your current menu items and identify which preparation tasks consume the most time and labor. Consider whether your dishes require more vegetable preparation, sauce making, and general food processing, or if meat grinding and protein preparation dominate your prep work. Evaluate upcoming menu changes or seasonal offerings that might benefit from either machine’s capabilities.

Determine Your Versatility Needs

Evaluate whether your kitchen benefits more from a versatile multi-purpose machine or a specialized single-purpose appliance. Food processors adapt to various tasks throughout the day, making them valuable for restaurants with diverse menus and limited equipment budgets. Meat grinders serve specific functions exceptionally well, which makes them ideal for establishments that process significant quantities of meat.

Evaluate Available Kitchen Space

Assess your kitchen layout and storage capacity to determine which machine fits your operational flow. Food processors typically require less dedicated space since they handle multiple functions, replacing several manual tools. Food grinders need designated areas for safe meat processing and proper sanitation protocols. Consider counter space, storage for attachments, and proximity to cleaning stations when making your decision.

Compare Ongoing Maintenance Needs

Factor in the time and cost requirements for maintaining each type of equipment. Food processors require regular and more extensive cleaning, but they generally need less intensive maintenance procedures. Meat grinders demand strict sanitation protocols and more frequent deep cleaning to maintain food safety standards. Consider your staff’s capacity for maintenance tasks and whether you have adequate time for proper equipment care during busy service periods.

Making Your Final Equipment Decision

Choosing between food processors and meat grinders depends on your restaurant’s specific needs, menu requirements, and operational goals. Food processors offer unmatched versatility for diverse kitchens that require multiple preparation capabilities, while meat grinders deliver exceptional performance for restaurants focused on protein preparation.

Consider your menu’s demands, available space, and staff capabilities when making this important equipment decision. The right choice will enhance your kitchen’s efficiency, improve food quality, and support your restaurant’s long-term success through better preparation methods and cost control.