Aug 13th 2025

The Complete Guide to Pizza Dough Equipment

Behind every delicious pizza is great dough, and behind that great dough is exceptional equipment. Whether you’re running a busy slice shop or launching a new artisan concept, your dough setup will determine your output, consistency, and quality. Having the right tools not only speeds up production but also elevates the final product, making every crust easier to shape, proof, and bake to perfection.

Explore this complete guide to pizza dough equipment so you’ll know what it takes to make dough that performs as well as it tastes.

Dough Mixers

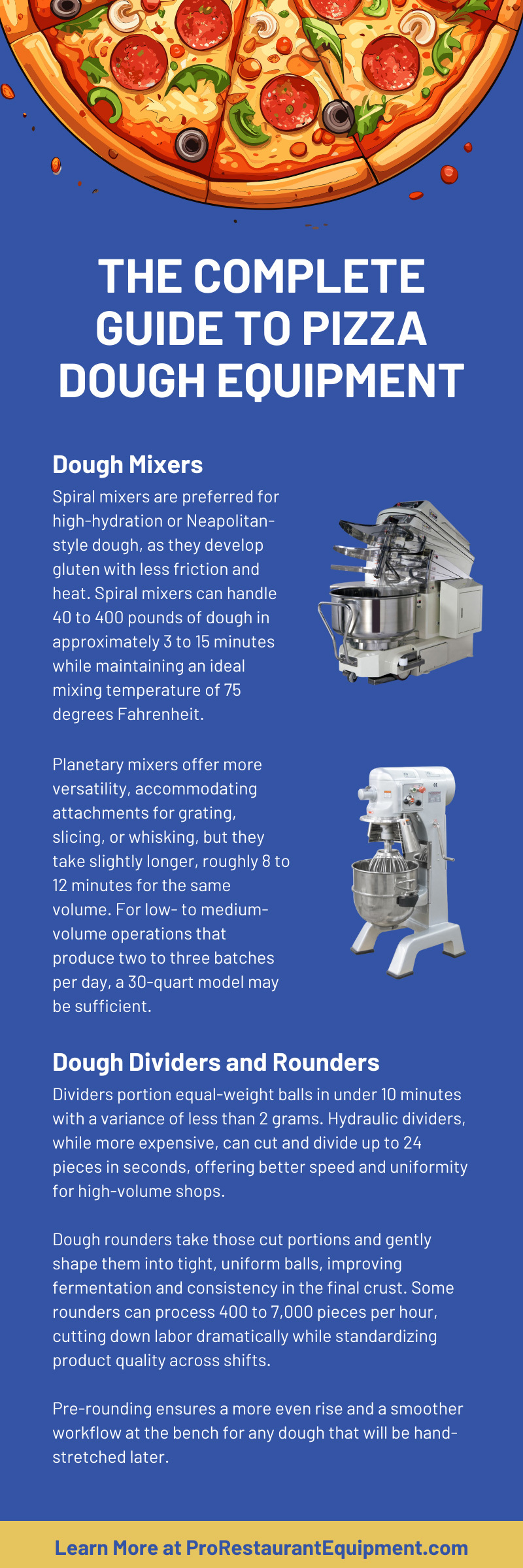

Dough mixing is where a pizza starts, which means investing in the right type of mixer is nonnegotiable. Most pizzerias use either spiral or planetary mixers, depending on dough style and volume.

Spiral mixers are preferred for high-hydration or Neapolitan-style dough, as they develop gluten with less friction and heat. Spiral mixers can handle 40 to 400 pounds of dough in approximately 3 to 15 minutes while maintaining an ideal mixing temperature of 75 degrees Fahrenheit.

Planetary mixers offer more versatility, accommodating attachments for grating, slicing, or whisking, but they take slightly longer, roughly 8 to 12 minutes for the same volume. For low- to medium-volume operations that produce two to three batches per day, a 30-quart model may be sufficient.

Higher-volume shops often rely on 60-quart models that handle 60 to 70 pounds of dough per batch, helping them stay ahead of the rush without overloading equipment.

Dough Dividers and Rounders

Once the dough is mixed, it must be portioned precisely. Manual dough cutting with a scale can take up to 80 to 100 minutes per 100 dough balls—time that could be reclaimed with a semi-automatic divider.

Dividers portion equal-weight balls in under 10 minutes with a variance of less than 2 grams. Hydraulic dividers, while more expensive, can cut and divide up to 24 pieces in seconds, offering better speed and uniformity for high-volume shops.

Dough rounders take those cut portions and gently shape them into tight, uniform balls, improving fermentation and consistency in the final crust. Some rounders can process 400 to 7,000 pieces per hour, cutting down labor dramatically while standardizing product quality across shifts.

Pre-rounding ensures a more even rise and a smoother workflow at the bench for any dough that will be hand-stretched later.

Pizza Dough Press Machine

Hand-stretching is a skilled task, but it’s not always the most efficient. A pizza dough press machine simplifies the shaping process, producing identical crusts quickly without compromising on texture. In fast-paced kitchens, heated presses can shape up to 400 dough portions per hour, keeping production moving without tearing or overworking the dough.

Press machines are particularly useful for operations that offer multiple pizza sizes or styles. With adjustable thickness settings and heated plates, certain press machine models allow for both speed and precision.

Many presses also feature non-stick surfaces, minimizing the need for dusting flour and reducing cleanup time by up to 30 minutes per shift. For kitchens that prioritize efficiency and consistency, a pizza press machine isn’t just helpful; it’s essential.

Refrigeration and Dough Holding

Proper refrigeration is critical for dough development. Walk-in coolers or reach-in refrigerators are used to cold-proof dough balls at 39 degrees Fahrenheit for between 24 and 96 hours. This fermentation window develops flavor and prevents over-proofing.

Refrigerated prep tables also play a role in dough handling. Keeping sauce, cheese, and toppings at food-safe temperatures directly at the workstation prevents constant back-and-forth. Undercounter refrigerators positioned near the shaping station reduce handling time by up to 15 minutes per shift and help preserve dough temperature before baking.

Proofing and Dough Storage

Once divided and rounded, dough needs time to rise and rest. Proofing cabinets provide a controlled environment, typically set between 75 and 90 degrees Fahrenheit and with 75 to 80 percent humidity, to activate yeast and relax gluten. Dough held in these conditions for 24 to 72 hours offers a more complex flavor and a lighter, airier crust. Full-height cabinets with pan racks allow for vertical storage and consistent results for kitchens proofing large batches simultaneously.

For longer fermentation schedules, dough trays with lids are the go-to solution. Trays are usually stacked and designed to fit into reach-in coolers or walk-ins. Lidded trays prevent moisture loss over the cold-proofing period. Proper labeling—specifically date, time, and target bake window—is crucial to maintain tight rotation and minimize waste.

Pizza Prep and Assembly Stations

Pizza prep tables act as the control center of your make line. These refrigerated stations feature topping rails for sauces, cheese, and fresh ingredients, along with a cutting board workspace. Most units come with pre-configured pan spaces to keep ingredients organized and chilled at or below 41 degrees Fahrenheit.

Placement matters. Well-positioned prep tables eliminate extra steps between the dough press, sauce ladle, and oven peel. Integrated drawers or undercounter shelves store extra toppings or backup cheese, reducing the need to restock during a rush.

On a 300-pie day, an efficient layout can shave up to 40 minutes off assembly time. It also helps standardize portions, which cuts costs and improves consistency.

Essential Pizza Tools

Sometimes, the smallest tools can make the biggest difference. Dough dockers prevent bubbling by gently perforating crusts before baking. Pizza wheels and mezzalunas offer fast slicing for both whole pies and individual portions. And portion scales keep cheese costs in check by ensuring every pizza receives the exact target weight.

Peels and screens also play a role in baking dough. Aluminum peels with long handles are ideal for maneuvering pies in and out of deck ovens, while wood peels reduce sticking when launching raw dough.

Screens help produce crispier crusts by allowing airflow underneath. For shops using conveyor ovens, screens simplify handling and speed up loading during back-to-back orders.

Cleaning and Compliance Tools

Good dough starts with clean equipment. All dough prep equipment, including mixers, dividers, and presses, must be cleaned and sanitized routinely during active use. This requires access to proper three-compartment sinks or commercial dishwashers.

Handwashing sinks should be placed within 20 feet of the dough station and plainly marked. Food-safe sanitizers must be clearly labeled and stored away from prep areas.

Thermometers used during dough refrigeration or ingredient storage should be calibrated weekly to maintain food safety compliance.

Precision Is the Advantage

In dough production, there’s no hiding from inconsistency. One under-kneaded batch or poorly proofed tray can throw off your entire service. The right equipment turns guesswork into repeatable quality, from the first stretch to the final slice. By following this complete guide to pizza dough equipment, your kitchen will be ready with tools that perform as hard as your team does.

Pro Restaurant Equipment connects restaurants directly with trusted manufacturers, offering high-performance tools at reasonable prices. No catalogs, no commissions—just equipment that helps you serve pizza worth remembering.